Introduction of new type resin blank material for cutting process

「There is limitation of blank material for cutting process provided by material manufacturer. For technician of product development, blank material with mass production potential will be more desired. 」It is the strong demand of customer.

Our advantage of IMP processing method lies in the control of pore. Blank material for cutting process produced by this method have advantage to correspond by relatively small scale production during injection molding. Therefore , we can provide low price blank material with short lead time and suitable for small scale production, which is also pore-free and has no stack interface.

- All below troubles related to this kind of blank material for cutting could be settled.

- Material for cutting that you want. was unavailable from your supplier

- You want to buy blank with special filling material

- You are looking for colored resin

- You expect to correspond with short lead time

- The less usage amount the better

- once, you tried injection molding ,but fail because of bubbles

- once, you tried stack molding ,but fail because of insufficient intensity of stack interface

Production condition

- Specialized material of injection molding

- Materials in resin manufacturer’s catalogue. Or material qualified with resin basic data.

- thermoplastic resin

- Both hard and soft material are acceptable

- Special material like fluoride and PVC are not allowed to use

Matters need attention of developer

Our cutting material is produced by injection compression molding. Although the technology is the same with cutting material (extrusion molding product ) in the past. But injection molding product has a relatively intense surface layer called Skin Layer.

The surface layer will be removed during cutting process, and the core layer will be used for production. Therefore, compare with the original injection molding parts, the intensity of cutting part will show a slight declining tendency.

Order bulk material for cutting

Material specified by customer will be produced and sold as bulk blank material over 25kg

- Producible material range from normal engineering plastic like PP and PE to super engineering plastic like PEEK and PPS.

- Additives is applicable to all material.

- Product output quantity will be different due to material nature, molding condition and anneal temperature.

(After the second time production, output quantity will increase because the production conditions are confirmed )

Bulk mold series we are offering now

- 70mm×70mm×25mmt

- 150mm×150mm×10mm~40mmt Variable corresponding

- 100mm×205mm×10mm~55mmt Variable corresponding

【Please provide below information when order cutting material 】

- Basic information of material (Resin raw material, additives variety and quality )

- minimum size of the bulk material (product size of cutting process need to take into consideration )(Adjustment will be made according to situation )

- Resin temperature .mold temperature (Please cooperate in order to confirm molding condition as early as possible )

- Anneal temperature (if related information could be achieved )

- Quality needed

- Material free offer/ Purchase by us

- Expected delivery time

※ If you provide the size information of material with fiber additive (glass, carbon), the size need to be limited.

【When ordering cutting material ,please make sure you notice below matters 】

Point 1

Although our bulk material has thermo plasticity, stress crack or uncontrollable pore could be happened. It’s only for pilot run, please understand.

Point 2

Our bulk materials is made by injection molding technique, although we apply inner stress that will not hinder the cutting process, but stress by no means equals zero. Please pay more attention of this matter during cutting process.

If you want to order, please click the button on the bottom to fill in purchase information, or contact us directly.

Heartfelt voice from customer

IMP bulk material injection process

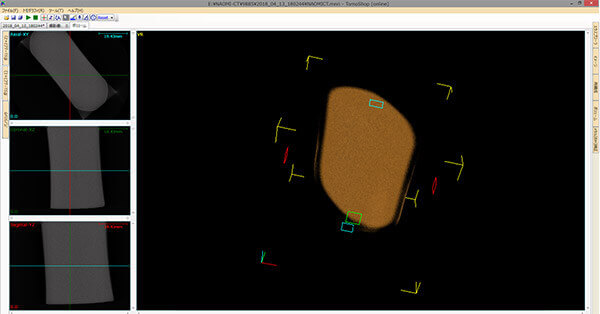

Quality management method

We apply nondestructive examination method (X-RAY CT) to manage quality of bulk material production, during which inner pore and crack are inevitable.

Produced by RF Company X-ray CT equipment

Provide nondestructive examination and internal defect free product